"Matt Brown" (superfastmatt)

"Matt Brown" (superfastmatt)

10/31/2016 at 13:20 • Filed to: DIY, Matt Brown, Making medical devices in the comfort and safety of your home

42

42

27

27

"Matt Brown" (superfastmatt)

"Matt Brown" (superfastmatt)

10/31/2016 at 13:20 • Filed to: DIY, Matt Brown, Making medical devices in the comfort and safety of your home |  42 42

|  27 27 |

When confronted with the opportunity to buy something for twenty dollars, I always think “I bet I could build that for free,” and then proceed to spend a hundred dollars in tools so that I can build it for free. Then I spend twenty dollars on beer to celebrate the money I saved. So when my doctor said “You’ll need to buy a walking cane,” I thought,

Buy? I have a pile of metal and a welder

. So I bought twenty dollars of beer and got to work.

Before getting started, I needed to find some inspiration. A brief web search of canes confirms that cane users fall into one of two categories: Grandma, and Fedora Guy. Grandma has the aluminum adjustable cane with the four separate feet and, sometimes, tennis balls on the bottom. Fedora guy doesn’t need a cane any more than he needs a goblin holding a crystal ball, but for some reason has decided to purchase both of these items attached to each other.

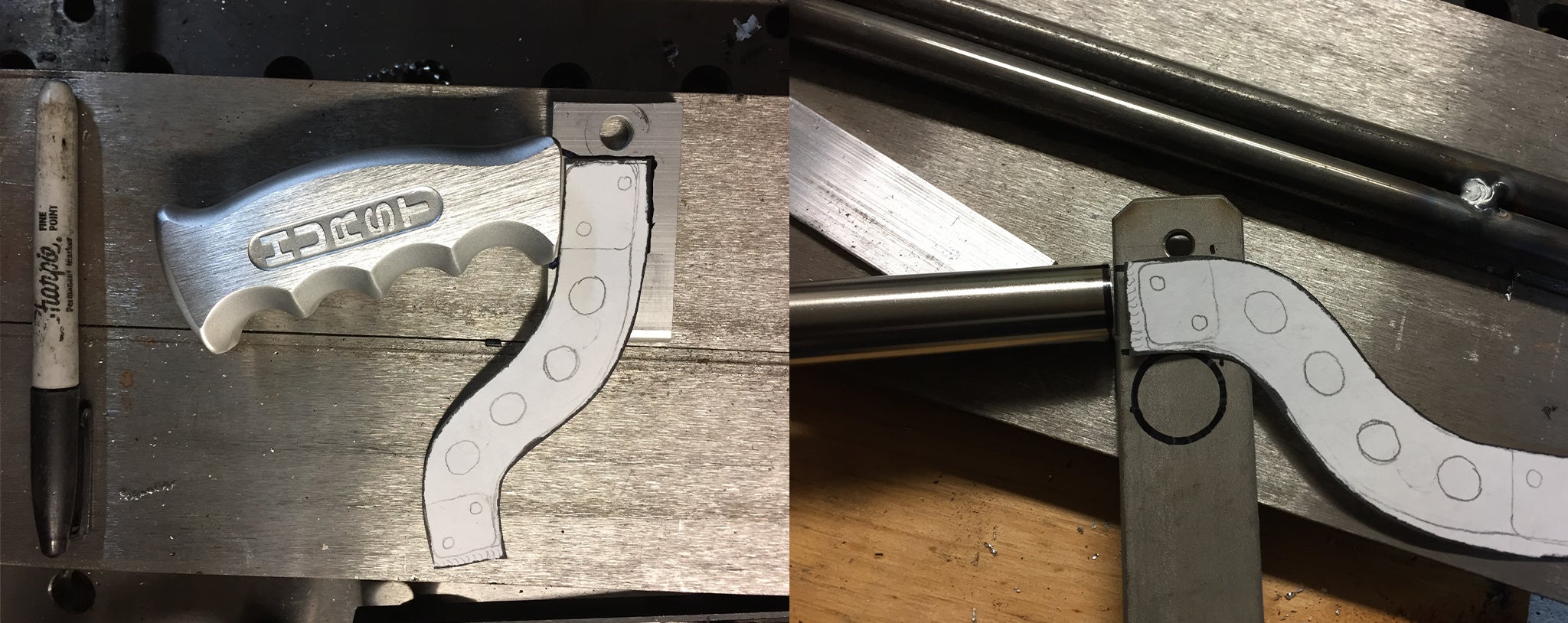

You know what, forget about getting ideas, let’s just see what I have in my garage. I have tubes of metal, sheets of metal, some nuts and bolts, and oh, what is this? A Hurst pistol grip shift handle? Jackpot.

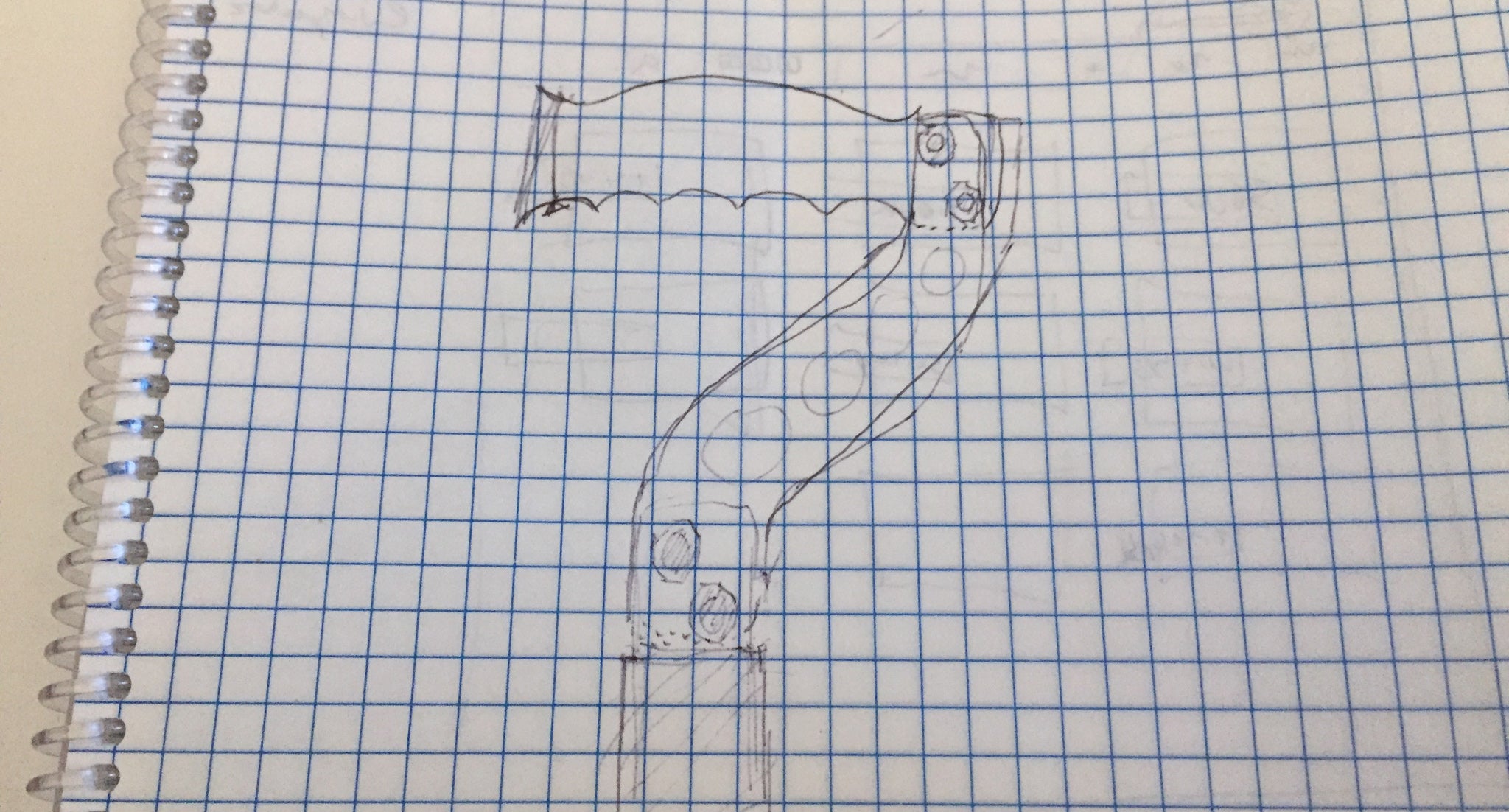

Before getting started, I pulled up my CAD software and did a full 3D model and ran both a modal and non-linear Finite Element Analy-no not really, I just drew it on a piece of paper. The cane’s ability to not collapse under my weight is a function of intuition and a huge safety factor.

Bonus Engineering Fact: The emblem of the American Society of Mechanical Engineers contains the latin phrase “ non loqui sed facere ” which means “intuition and a huge safety factor.”

I draw gud

After getting a design that I liked, the next step was to make a scale drawing and use it to trace out the metal to cut. I needed to weld an aluminum extension onto the shifter handle, and a stainless extension onto the shaft, so I cut those out of some scrap metal I had.

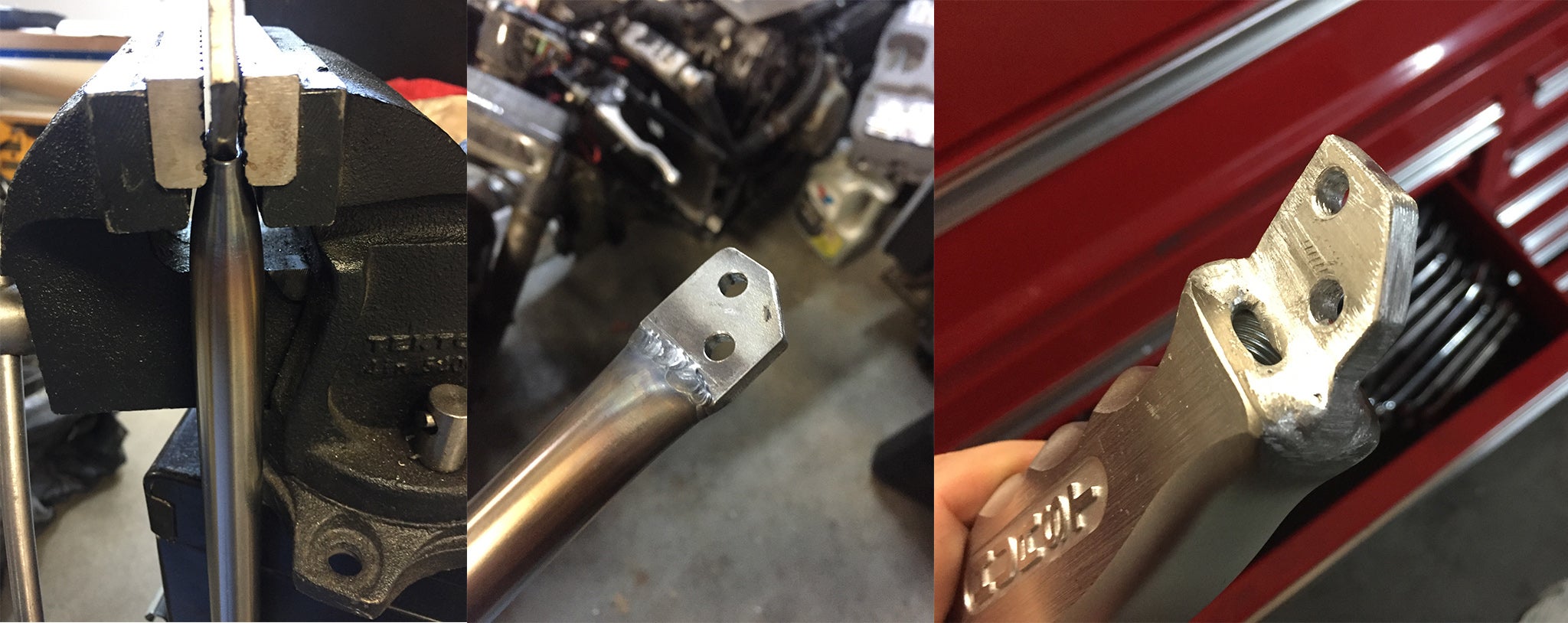

After those were cut out, I mashed the tube with a vice, placing the extension I had just cut into the middle of the part I was squishing to prevent it from collapsing too far in like a figure eight. Once that was flattened, I welded the extensions onto their respective parts and cleaned them up with a file.

I weld gud

The next step was to cut out the aluminum pieces that would connect the handle to the shaft. This would be a breeze with a waterjet, but if I go to the waterjet guy at work and say “Hey man, can you slip this in with your next job,” he will respond, “Dude, you haven’t worked here for two years; how did you even get in the building?”

Whatever, I have a bandsaw.

So I bansawed out the pattern, drilled the holes, and then used my favorite tool ever of the week to deburr the holes.

Once those pieces were made, it was just a matter of lining everything up, clamping it down, and drilling the holes for the fasteners. Once that was done, I bolted everything together, cut the shaft to the correct height, added the rubber bumper thing, and bam! Walking cane.

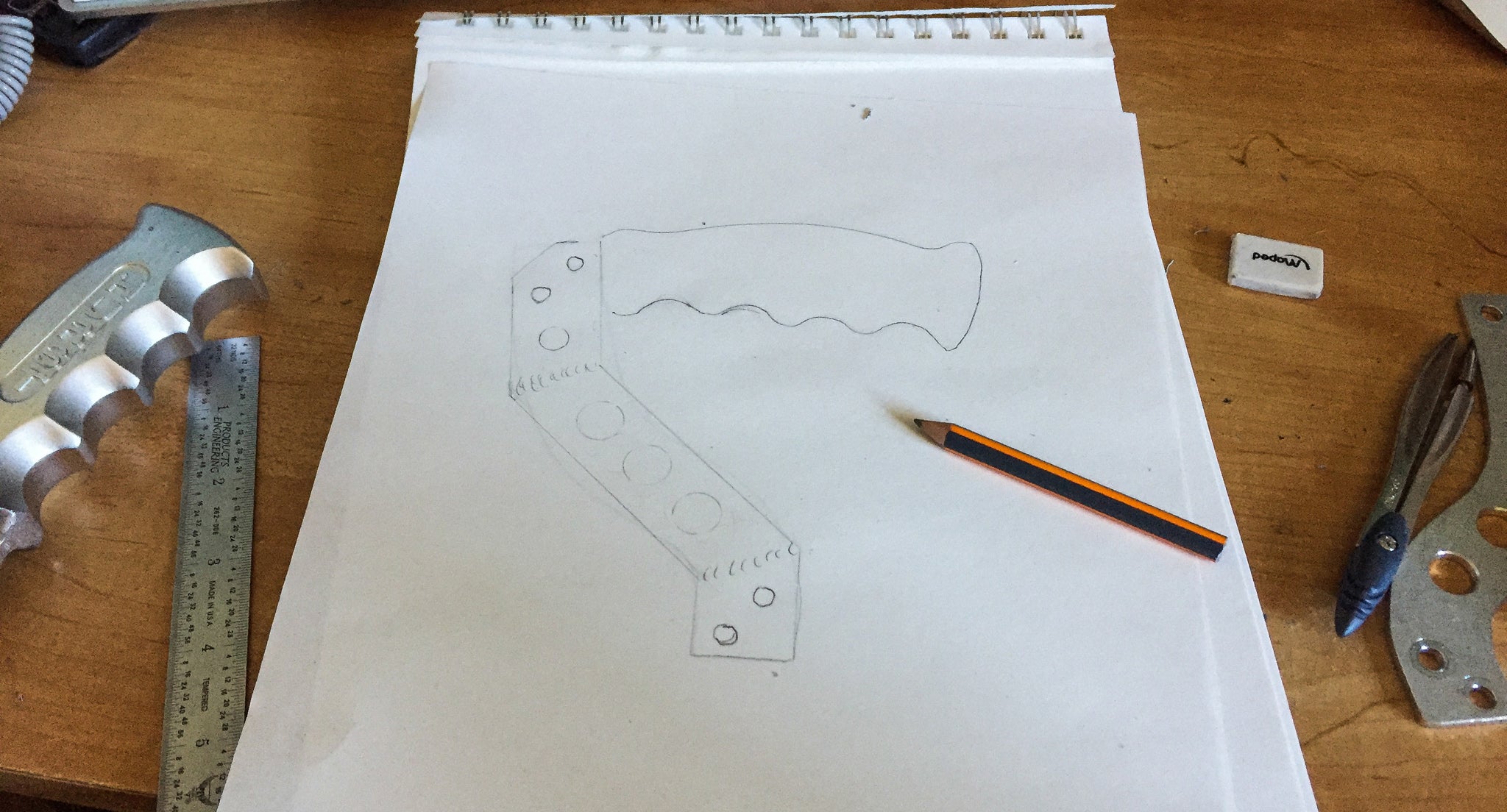

You know what? I don’t love that. It’s too… Flowy? Swoopy? It needs more angles. More… Metal.

Fortunately, I have more metal. Back to the drawing board.

I’m getting better at drawing

Once I had a good 1:1 drawing that I liked, I cut out the middle connecting piece and used it as a pattern to cut some 1” wide steel bar. I then welded the bar together, drilled the holes, and used my favorite tool ever of the week again

After that was done and cleaned up, I put the fasteners back in and bam! Walking cane.

The end.

Rusty Vandura - www.tinyurl.com/keepoppo

> Matt Brown

Rusty Vandura - www.tinyurl.com/keepoppo

> Matt Brown

10/31/2016 at 13:26 |

|

Let’s be clear: you fabricated a $300 cane in order to avoid spending twenty bucks. I approve.

Future next gen S2000 owner

> Matt Brown

Future next gen S2000 owner

> Matt Brown

10/31/2016 at 13:28 |

|

Speed holes make everything better. It’s science.

iSureWilll

> Matt Brown

iSureWilll

> Matt Brown

10/31/2016 at 13:30 |

|

Badass cane. +1 for fabrication skills.

The Crazy Kanuck; RIP Oppositelock

> Matt Brown

The Crazy Kanuck; RIP Oppositelock

> Matt Brown

10/31/2016 at 13:30 |

|

Enginnering: Looking simple thing, then making an overly complex solution.

functionoverfashion

> Matt Brown

functionoverfashion

> Matt Brown

10/31/2016 at 13:34 |

|

Tell me there’s a tennis ball on the bottom

Demon-Xanth knows how to operate a street.

> Matt Brown

Demon-Xanth knows how to operate a street.

> Matt Brown

10/31/2016 at 13:36 |

|

On the plus side, when you hit someone with your cane, the mofo is going down!

MonkeePuzzle

> Matt Brown

MonkeePuzzle

> Matt Brown

10/31/2016 at 13:39 |

|

we never saw the base of the cane, so i assume it spreads into four legs and has tennis balls attached.

KeedyT

> Matt Brown

KeedyT

> Matt Brown

10/31/2016 at 13:40 |

|

“my favorite tool ever of the week” - this is perfect and shall be reused in conversation until someone tells me to stop!

MonkeePuzzle

> Matt Brown

MonkeePuzzle

> Matt Brown

10/31/2016 at 13:40 |

|

pistol grip and long tube, please go to an airport and get a TSA impression on it. for science

uofime-2

> Matt Brown

uofime-2

> Matt Brown

10/31/2016 at 13:48 |

|

The emblem of the American Society of Mechanical Engineers contains the latin phrase “non loqui sed facere” which means “intuition and a huge safety factor.”

You’ve mixed up the mottos of the ASME and ASCE

Matt Brown

> uofime-2

Matt Brown

> uofime-2

10/31/2016 at 13:49 |

|

I thought ASCE was “Just look it up in the book.”

shop-teacher

> Matt Brown

shop-teacher

> Matt Brown

10/31/2016 at 14:15 |

|

Nicely done!

Phyrxes once again has a wagon!

> Matt Brown

Phyrxes once again has a wagon!

> Matt Brown

10/31/2016 at 14:38 |

|

Nicely done, -1 Internet point for not using this an excuse to buy a plasma cutter though.

Tripper

> Matt Brown

Tripper

> Matt Brown

10/31/2016 at 15:32 |

|

“I always think “I bet I could build that for free,” and then proceed to spend a hundred dollars in tools so that I can build it for free.”

Story of my life. Neat cane by the way!

davesaddiction @ opposite-lock.com

> Matt Brown

davesaddiction @ opposite-lock.com

> Matt Brown

10/31/2016 at 15:50 |

|

So, you’re pretty much a pimp now, right?

Matt Brown

> davesaddiction @ opposite-lock.com

Matt Brown

> davesaddiction @ opposite-lock.com

10/31/2016 at 16:03 |

|

Pistol grip pimp™

davesaddiction @ opposite-lock.com

> Matt Brown

davesaddiction @ opposite-lock.com

> Matt Brown

10/31/2016 at 16:27 |

|

I’m guessing you could make some money selling these...

Is the cane a temporary thing, or will you have it for some time?

just-a-scratch

> Matt Brown

just-a-scratch

> Matt Brown

10/31/2016 at 18:53 |

|

That’s a neck of a stick. Good work there.

“pistol grip” makes me think of using an actual pistol frame as the cane grip. Then find a way to insert a pocket knife or multitool in place of the magazine. getting the mag release to work would be difficult, but really neat.

Funktheduck

> davesaddiction @ opposite-lock.com

Funktheduck

> davesaddiction @ opposite-lock.com

10/31/2016 at 19:57 |

|

I saw a girl with “pimp” tattooed in big letters across her upper back yesterday.

wafflesnfalafel

> Matt Brown

wafflesnfalafel

> Matt Brown

10/31/2016 at 23:26 |

|

This is like easy top 5 best oppo posts ever... (And if anybody messes with you that thing will leave a nice mark upside the head.)

Svart Smart, traded in his Smart

> Matt Brown

Svart Smart, traded in his Smart

> Matt Brown

11/01/2016 at 00:33 |

|

Beautiful work.

Mr. Ontop, No Strokes, No Smokes...Goes Fast.

> Matt Brown

Mr. Ontop, No Strokes, No Smokes...Goes Fast.

> Matt Brown

11/01/2016 at 01:34 |

|

As someone who was recently in need of a cane, but has managed to Physical Therapy myself out of it, I admire this a lot. I have a cane and only need it occasionally, but it is not nearly funky enough for my tastes. Any shot I could get a quote from you on something like this only with a 5-6 speed shifter ball on there?

Matt Brown

> davesaddiction @ opposite-lock.com

Matt Brown

> davesaddiction @ opposite-lock.com

11/01/2016 at 02:14 |

|

About a month

Andy Sheehan, StreetsideStig

> Matt Brown

Andy Sheehan, StreetsideStig

> Matt Brown

11/01/2016 at 08:40 |

|

This is FP material, right here.

davesaddiction @ opposite-lock.com

> Matt Brown

davesaddiction @ opposite-lock.com

> Matt Brown

11/01/2016 at 08:49 |

|

Glad to hear it’s just a short time.

Rusty Vandura - www.tinyurl.com/keepoppo

> Matt Brown

Rusty Vandura - www.tinyurl.com/keepoppo

> Matt Brown

11/01/2016 at 15:18 |

|

Did you consider grinding the weld beads flush?

Tac

> Matt Brown

Tac

> Matt Brown

11/17/2016 at 15:34 |

|

does it cost more then cheap china imports? of course but shit,

its the spirit of the DYI and creativity that is respect with projects like these